This plant is for production of bio-diesel BD 100 euro 7 purity (using animal and vegetable fats and oils with the presence of free fatty acids - FFA). The plant's capacity on a daily basis is 15T bio diesel BD 100 euro 7 .

This plant is for production of bio-diesel BD 100 euro 7 purity (using animal and vegetable fats and oils with the presence of free fatty acids - FFA). The plant's capacity on a daily basis is 15T bio diesel BD 100 euro 7 .

We provide installation, commissioning, staff training and giving warranty for 20 years on our production reactor and we transfer producers guarantee for the other parts that are contracted (electric motors, pumps, heater, valves, displays etc ...).

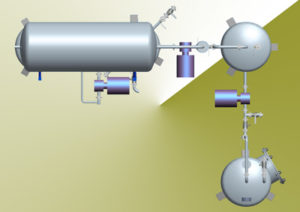

To install the plant, we need a concrete slab, reinforced, 10cm thick, width 10m, length 10m, and canopy height of 6m. The plant needs three-phase electricity with consumption of up to 45 kW. As well plant need water and drain.

Around the plant has to be done fire fighters path that will be used for transport of feedstock (raw materials) and finished products as well.

At the end of the process of production there is reservoir for the finished product with capacity of 100 t. There is a choice of the reservoirs for raw materials, but it is recommended to store them in barrels or tanks and flexible reservoirs in witch they can be transported.

In addition of technologists for overseeing the production there is 2 more workers needed on the plant.

Full production is ecological. The production process has no waste polluting the environment and all by products are either reused or used in bio-diesel.

One kg or liter of fat gets a 1.1 lit. BD 100 euro 7 with use of methanol as a catalyst.

The plant uses clean raw materials from oil and animal fat and waste (used) oil and fat (recommended and profitable).

The calculation for Serbia shows that the raw material must be imported in order to generate higher profits.

Technologies developed by our engineers.